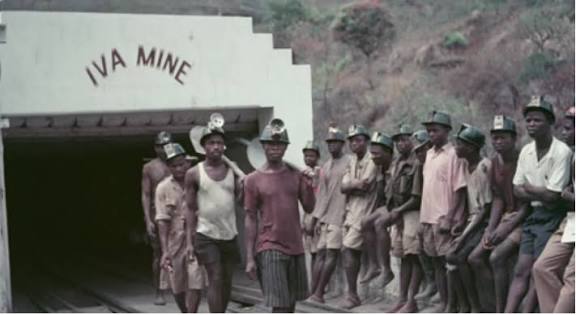

Namibia’s investment promotion body announced the commencement of construction on Monday for Africa’s inaugural decarbonized iron plant, which will rely solely on green hydrogen as its power source.

The steelmaking sector, recognized as one of the most environmentally detrimental industries globally, is actively working to transition from coal-fired plants to the utilization of decarbonized iron.

The Oshivela project in western Namibia, supported by the German federal government with a 13 million euro investment, will utilize renewable energy to produce 15,000 tonnes of iron annually, completely free from carbon emissions, as stated by the Namibia Investment Promotion and Development Board (NIPDB).

Last year, Namibia made history as the first African nation to enter into an agreement with the European Union, committing to provide the bloc with green hydrogen and essential minerals crucial for clean energy technology.

Plant production is scheduled to commence in the last quarter of 2024, with future plans to gradually increase production to reach an annual output of 1 million metric tons of green iron.

According to Rainer Baake, Special Envoy for German-Namibian Climate and Energy Cooperation, the iron produced at the plant can serve as an initial product for steel production in Germany, contributing to the creation of green steel used in the manufacturing of wind turbines and vehicles.

The project’s developers, a consortium comprising German and Namibian firms, announced that the plant will employ HyIron technology. This process involves the utilization of green hydrogen to process iron ore in a rotary kiln.